Thorium’s Promise: A New Dawn for Nuclear Energy

The world stands at a critical juncture in its energy narrative. The escalating impacts of climate change, coupled with growing global energy demands, necessitate a radical rethinking of our energy sources. The relentless pursuit of sustainable and efficient energy sources has led researchers and engineers back to an element with immense potential: thorium. Advanced thorium reactor designs are not mere incremental improvements; they represent a paradigm shift in how we approach nuclear energy, promising safer, cleaner, and more abundant power for generations to come.

This article will explore the innovative technologies and concepts driving this nuclear renaissance, examining the potential of thorium to reshape the energy landscape. Thorium, a naturally occurring radioactive element, offers a compelling alternative to uranium in nuclear reactors. Unlike uranium-based reactors, which rely on a relatively scarce isotope (U-235) and produce significant amounts of long-lived nuclear waste, thorium reactors utilize the more abundant thorium-232 isotope and can be designed to minimize waste production. The thorium fuel cycle also presents inherent advantages in terms of nuclear proliferation resistance, as it produces less plutonium, a key ingredient in nuclear weapons.

This inherent safety and waste-reduction potential positions thorium reactors as a potentially transformative technology in the pursuit of clean and sustainable energy. One promising avenue for thorium utilization lies in molten salt reactors (MSRs). These advanced reactor designs employ liquid fluoride salts as both the fuel carrier and coolant, enabling operation at high temperatures and low pressures. This unique configuration enhances safety because the liquid fuel naturally expands if overheated, slowing the nuclear reaction and preventing meltdowns.

Furthermore, MSRs can be designed to operate as breeders, producing more fissile material than they consume, further extending the fuel supply and reducing the need for extensive mining. Several countries, including China and India, are actively pursuing MSR technology, recognizing its potential to provide a secure and sustainable energy source. Another design is the accelerator-driven system (ADS), where a particle accelerator generates neutrons to initiate and sustain the nuclear reaction in thorium fuel. This offers enhanced control and safety, allowing for subcritical operation, minimizing the risk of uncontrolled chain reactions.

The promise of thorium reactors extends beyond safety and waste reduction. Thorium is significantly more abundant than uranium, ensuring a more secure and stable fuel supply for future generations. Moreover, advanced reactor designs can be optimized to operate at higher efficiencies, extracting more energy from the fuel and reducing the overall environmental footprint. While technological hurdles and implementation challenges remain, the potential benefits of thorium reactors are undeniable. By exploring these innovative technologies and fostering international collaboration, we can unlock the full potential of thorium and usher in a new era of clean, safe, and sustainable nuclear energy.

The Thorium Fuel Cycle: Abundance and Reduced Waste

Unlike conventional uranium-based reactors that primarily rely on the uranium fuel cycle, thorium reactors leverage the thorium fuel cycle, presenting a compelling alternative with distinct advantages. The most prominent of these is thorium’s abundance; it is estimated to be three to four times more plentiful in the Earth’s crust than uranium. This significantly reduces concerns about resource depletion, offering a more sustainable long-term fuel supply for nuclear energy. For instance, countries like India, with substantial thorium reserves, view thorium reactors as a crucial component of their future energy security, reducing reliance on imported uranium and bolstering their domestic energy production capabilities.

This abundance directly addresses a key challenge in the broader context of nuclear energy: ensuring a stable and accessible fuel supply for decades to come. Beyond abundance, the thorium fuel cycle offers significant benefits in terms of nuclear waste management and nuclear proliferation risks. Thorium reactors produce substantially less plutonium and other long-lived transuranic waste products compared to uranium reactors. This reduction simplifies the complexities and long-term costs associated with nuclear waste disposal, a major concern for public acceptance of nuclear energy.

Moreover, the inherent properties of the thorium fuel cycle make it more resistant to nuclear proliferation. The primary fissile material produced in a thorium reactor is Uranium-233, which is typically contaminated with Uranium-232, a strong gamma emitter, making it difficult to weaponize without sophisticated and costly processing. This inherent proliferation resistance enhances the security profile of thorium-based nuclear energy. Molten Salt Reactors (MSRs) represent a particularly promising advanced reactor design often coupled with the thorium fuel cycle.

These reactors utilize liquid fluoride salts as both the fuel carrier and coolant, enabling operation at high temperatures and low pressures. This design offers inherent safety features, as the liquid fuel naturally expands if overheated, slowing the nuclear reaction and preventing meltdowns. Furthermore, MSRs can be designed to operate as breeders, producing more fissile material than they consume, further extending the fuel supply and minimizing nuclear waste. Ongoing research and development efforts are focused on overcoming material challenges associated with the corrosive nature of molten salts, paving the way for the deployment of safer, more efficient, and more sustainable nuclear energy systems. Accelerator-driven systems (ADS) are another viable option for thorium fuel cycle.

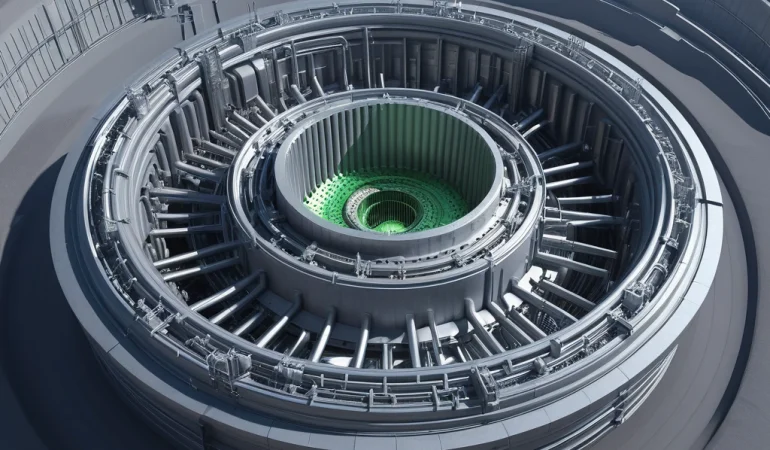

Molten Salt Reactors: Inherent Safety and Efficiency

Molten Salt Reactors (MSRs) represent a significant leap forward in advanced thorium reactor design, offering a pathway to cleaner and more sustainable nuclear energy. Unlike traditional solid-fueled reactors, MSRs utilize a liquid fluoride salt, typically composed of lithium, beryllium, and thorium fluorides, as both the fuel carrier and the coolant. This innovative approach allows the reactor to operate at high temperatures, often exceeding 700 degrees Celsius, while maintaining low pressures, significantly reducing the risk of catastrophic failures associated with pressurized water reactors.

The high operating temperature also enhances the thermodynamic efficiency of the power plant, allowing for greater electricity generation from the same amount of nuclear fuel, thereby contributing to the overall clean energy profile of thorium reactors. This is a departure from conventional nuclear energy systems and a key reason why MSR technology is viewed as a next-generation solution. The inherent safety characteristics of MSRs are a major advantage in the realm of nuclear energy. The liquid fuel’s natural expansion when overheated provides a built-in negative feedback mechanism, automatically slowing the nuclear reaction and preventing meltdowns.

This contrasts sharply with conventional reactors, where active cooling systems are essential to prevent fuel damage. Moreover, MSR designs often incorporate a freeze plug at the bottom of the reactor vessel. In an emergency, this plug melts, allowing the molten salt fuel to drain into a passively cooled catch tank, effectively shutting down the reactor without any external intervention or human action. This passive safety feature is a crucial element in mitigating nuclear proliferation risks, as it reduces the reliance on complex safety systems that could be compromised.

Furthermore, MSRs operating on the thorium fuel cycle offer a compelling solution to the nuclear waste challenge. By primarily producing short-lived fission products and significantly reducing the generation of long-lived transuranic waste, MSRs minimize the long-term environmental burden associated with nuclear energy. The thorium fuel cycle also inherently limits the production of plutonium, a key material in nuclear weapons, thereby enhancing nuclear security. In addition, MSRs can potentially consume existing stockpiles of plutonium and other problematic nuclear materials, further contributing to non-proliferation efforts.

The combination of enhanced safety, reduced waste, and proliferation resistance makes molten salt reactors a promising technology for a sustainable and responsible nuclear energy future. Moreover, the development of MSR technology can potentially reduce our dependence on traditional Uranium based nuclear reactors. Recent advancements in materials science are addressing the challenges associated with the corrosive environment of molten salts. Researchers are developing specialized alloys and coatings that can withstand high temperatures and radiation exposure, ensuring the long-term integrity of reactor components. For example, the development of advanced nickel-based alloys with enhanced chromium content has shown promising results in resisting corrosion in molten fluoride salt environments. Ongoing research and development efforts are crucial for validating these materials and demonstrating their long-term performance under realistic operating conditions. These material innovations are essential for the successful deployment of MSR technology and its contribution to a cleaner and more sustainable energy future.

Accelerator-Driven Systems: Enhanced Control and Safety

Accelerator-Driven Systems (ADS) represent another promising avenue for thorium utilization, offering unique advantages over conventional reactor designs. In ADS, a particle accelerator generates a beam of high-energy particles, typically protons, that bombard a target material, such as lead or tungsten. This collision produces spallation neutrons, which then initiate and sustain the nuclear reaction within the thorium fuel. Unlike traditional reactors that rely on a self-sustaining chain reaction, ADS operates in subcritical mode, meaning the nuclear reaction is not self-sustaining without the continuous input of neutrons from the accelerator.

This inherent characteristic provides a significant safety advantage. Turning off the accelerator immediately halts the neutron production and, consequently, the nuclear reaction, offering a rapid and reliable shutdown mechanism independent of control rods or other mechanical systems. This feature is particularly attractive in the context of enhancing nuclear safety and preventing accidents. The subcritical operation of ADS offers enhanced control over the nuclear reaction and allows for greater flexibility in fuel composition. Because the system is not dependent on achieving criticality through fissile material concentration alone, ADS can effectively utilize thorium fuel with lower concentrations of fissile isotopes or even operate with nuclear waste as a fuel source.

This capability opens the door to transmuting long-lived radioactive waste products into shorter-lived or stable isotopes, potentially alleviating the challenges associated with long-term nuclear waste storage. Experts at CERN, for example, have been investigating ADS technology for decades, emphasizing its potential for both energy production and nuclear waste management. The ability to ‘burn’ nuclear waste while simultaneously generating clean energy positions ADS as a key technology in the pursuit of a closed thorium fuel cycle and a more sustainable nuclear future.

Furthermore, the inherent safety features of accelerator-driven thorium reactors significantly reduce the risk of nuclear proliferation. Because the reactor operates in subcritical mode and requires a continuous external neutron source, it is inherently more difficult to divert fissile materials for weapons production. The design also allows for careful monitoring of the neutron source and fuel composition, providing additional safeguards against misuse. While the technology is complex and requires significant investment in both accelerator and reactor infrastructure, the potential benefits of enhanced safety, waste transmutation, and proliferation resistance make ADS a compelling area of research and development in the field of advanced reactor design. As the world seeks cleaner and more sustainable energy sources, accelerator-driven systems offer a promising pathway to harness the potential of thorium while addressing the challenges associated with traditional nuclear energy.

Technological Hurdles and Implementation Challenges

Advanced thorium reactor designs, while promising a cleaner and more sustainable energy future, are not without their significant technological and societal challenges. The development of materials capable of withstanding the extremely corrosive environment of molten salts, a key component in many thorium reactor designs, and the intense radiation fields within the reactor core presents a formidable engineering hurdle. For example, alloys must be developed and tested that can resist corrosion from fluoride salts at temperatures exceeding 700°C for extended periods.

This requires extensive research in materials science, including the creation of new alloys and coatings, coupled with rigorous testing under simulated reactor conditions. The expense and time required for this materials qualification process can significantly impact the deployment timeline for thorium reactors. Furthermore, establishing a robust and complete thorium fuel cycle infrastructure is a complex undertaking requiring substantial investment and international collaboration. This infrastructure encompasses all stages, from thorium mining and processing to fuel fabrication, reactor operation, and ultimately, nuclear waste management and disposal.

Unlike the uranium fuel cycle, which is well-established, the thorium fuel cycle is still in its nascent stages. Significant investment is needed to develop efficient and environmentally responsible thorium mining techniques, as well as facilities for converting thorium into reactor-ready fuel forms. The back end of the fuel cycle also presents challenges, as the waste streams from thorium reactors, while reduced in volume and radiotoxicity compared to conventional reactors, still require careful management and long-term storage solutions.

Public perception and acceptance of nuclear energy, including thorium-based systems, remain critical factors influencing the widespread adoption of these advanced reactor designs. Decades of concern surrounding nuclear proliferation and nuclear waste have created deeply entrenched anxieties. Overcoming these anxieties requires transparent communication, robust safety regulations, and demonstrable evidence of the inherent safety advantages of thorium reactors. Furthermore, addressing concerns about the potential for diversion of thorium fuel for weapons purposes, even though it is significantly less prone to nuclear proliferation than uranium or plutonium, is essential for building public trust. Demonstrating a commitment to responsible waste management strategies and engaging in open dialogue with communities are crucial steps in fostering public acceptance and paving the way for the successful deployment of thorium reactor technology as a clean energy source.

Computational Modeling and Simulation: A Virtual Revolution

Computational modeling and simulation are indispensable tools in the advancement of thorium reactor technology, offering a virtual proving ground for designs before physical construction. Sophisticated computer codes, often leveraging high-performance computing clusters, are employed to simulate neutron transport within the reactor core, predict thermal-hydraulic behavior of coolants like molten salts, and model the complex thermo-mechanical behavior of fuel elements under extreme conditions. These simulations provide critical insights into reactor performance, safety margins, and potential failure modes, enabling engineers to optimize designs for enhanced efficiency and inherent safety.

For instance, detailed simulations can predict the temperature distribution within a molten salt reactor (MSR) core, ensuring that the salt remains within its operational temperature range and preventing potential corrosion or solidification issues. Such predictive capabilities are crucial for the successful deployment of advanced reactor designs. The application of computational fluid dynamics (CFD) is particularly relevant to molten salt reactors, where the fluid dynamics of the molten salt directly impacts heat transfer and neutronics. CFD simulations can model the complex flow patterns within the reactor, identifying areas of potential stagnation or excessive turbulence that could compromise performance or safety.

Furthermore, these simulations can be coupled with neutron transport codes to create multi-physics models that capture the interplay between fluid flow, heat transfer, and nuclear reactions. This integrated approach allows engineers to optimize the reactor design for maximum power output while maintaining a stable and safe operating environment. The data generated from these simulations also contributes to the development of more accurate and reliable reactor control systems, enhancing overall operational safety. Looking ahead, the integration of artificial intelligence (AI) and machine learning (ML) techniques promises to further revolutionize thorium reactor design and operation.

AI algorithms can be trained on vast datasets generated from simulations and experiments to identify patterns and correlations that would be difficult or impossible for humans to detect. This can lead to the discovery of novel design concepts, improved control strategies, and more accurate predictions of reactor behavior. Moreover, quantum computing holds the potential to dramatically accelerate reactor simulations, enabling the modeling of complex nuclear processes with unprecedented accuracy. For example, quantum simulations could provide a more detailed understanding of neutron interactions with thorium nuclei, leading to more efficient fuel cycle designs and reduced nuclear waste production. These advancements in computational technology are essential for realizing the full potential of thorium reactors as a clean, safe, and sustainable source of nuclear energy, contributing significantly to global clean energy initiatives and mitigating concerns about nuclear proliferation through optimized thorium fuel cycle management and advanced reactor designs.

Global Initiatives: India and China Lead the Way

Countries like India and China are at the forefront of global efforts to harness thorium reactor technology as a cornerstone of their long-term energy strategies. India, endowed with some of the world’s largest thorium reserves, has been a pioneer in exploring the thorium fuel cycle. Their multi-stage nuclear program envisions a gradual transition from Pressurized Heavy Water Reactors (PHWRs) to Advanced Heavy Water Reactors (AHWRs) and ultimately to fast breeder reactors that utilize thorium. The goal is to achieve energy independence and meet the growing electricity demand while minimizing reliance on uranium imports.

This ambition is not just theoretical; significant resources are being invested in research and development, including the construction of experimental thorium-based reactors. This commitment underscores the strategic importance of thorium for India’s energy security. China’s approach to thorium reactors is equally ambitious, with a particular focus on Molten Salt Reactor (MSR) technology. Recognizing the potential of MSRs for enhanced safety and efficiency, China has launched a significant research and development program aimed at mastering this advanced reactor design.

The Shanghai Institute of Applied Physics (SINAP) is leading the charge, with plans to build and operate demonstration plants in the near future. This initiative represents a substantial investment in next-generation nuclear energy technology, with the potential to revolutionize nuclear power generation. The Chinese government views thorium-based MSRs as a key component of its strategy to reduce carbon emissions and transition to a cleaner and more sustainable energy mix. Their commitment includes addressing challenges related to material science, fuel processing, and reactor operation, paving the way for commercial deployment.

Beyond India and China, other nations are also exploring the potential of thorium reactors, albeit at earlier stages of development. These include countries in Europe, North America, and Asia, who are conducting research on various aspects of thorium fuel cycles and advanced reactor designs. The appeal of thorium lies in its abundance, reduced nuclear waste production, and inherent safety characteristics. However, the successful deployment of thorium reactor technology requires sustained investment, international collaboration, and a concerted effort to overcome technological hurdles. As these global initiatives gain momentum, the prospect of a future powered by clean and sustainable nuclear energy from thorium becomes increasingly tangible. The collaborative spirit and knowledge-sharing among these nations are essential to unlock the full potential of this promising energy source and address the world’s growing energy demands while minimizing environmental impact and nuclear proliferation risks.

Economic Considerations: Balancing Costs and Benefits

The economic viability of advanced thorium reactors hinges on a complex interplay of factors, including upfront capital expenditures, fuel costs, operational expenses, and long-term nuclear waste management strategies. While the inherent abundance of thorium promises significantly lower fuel costs compared to traditional uranium-based nuclear energy, the initial investment required for thorium reactor construction and the establishment of a complete thorium fuel cycle represents a substantial economic hurdle. This includes the costs associated with mining, processing, and fabricating thorium fuel, as well as the development of specialized materials capable of withstanding the unique operating conditions within a thorium reactor, particularly in molten salt reactor (MSR) designs.

These factors necessitate a comprehensive economic analysis to accurately assess the long-term cost-effectiveness of thorium-based nuclear energy solutions. Government subsidies, international partnerships, and technological breakthroughs are crucial for improving the economic competitiveness of thorium reactors and accelerating their deployment as a clean energy source. Targeted research and development funding can drive innovation in reactor design, materials science, and fuel cycle technologies, leading to reduced capital costs and improved operational efficiency. For example, advancements in 3D printing techniques could potentially lower the cost of manufacturing complex reactor components.

Furthermore, international collaborations can facilitate the sharing of knowledge, resources, and expertise, accelerating the development and deployment of thorium reactor technology on a global scale. Streamlined regulatory frameworks that address the unique safety and environmental characteristics of thorium reactors are also essential for attracting private investment and fostering innovation in this promising field of nuclear energy. Beyond the direct costs, a comprehensive economic evaluation must also consider the broader societal benefits of thorium reactors, such as reduced nuclear proliferation risks and simplified nuclear waste management.

The thorium fuel cycle produces significantly less plutonium and other long-lived transuranic waste products compared to uranium reactors, potentially reducing the long-term costs and environmental burden associated with nuclear waste disposal. This advantage could translate into lower storage and disposal fees, as well as reduced risks of environmental contamination. Moreover, the inherent safety features of certain thorium reactor designs, such as MSRs and accelerator-driven systems (ADS), can minimize the risk of accidents and reduce the need for costly safety upgrades. By accounting for these broader benefits, policymakers and investors can gain a more accurate understanding of the true economic value of advanced thorium reactor technology as a sustainable energy solution.

Environmental Advantages: A Greener Nuclear Future

The environmental benefits of thorium reactors represent a significant advancement in nuclear energy technology, particularly in the pursuit of clean energy solutions. The reduced production of long-lived radioactive waste, a hallmark of the thorium fuel cycle, simplifies waste disposal logistics and dramatically curtails the long-term environmental impact compared to conventional uranium-fueled reactors. For example, while spent uranium fuel contains significant amounts of plutonium and minor actinides that remain radioactive for tens of thousands of years, thorium reactors, especially molten salt reactor designs, produce comparatively smaller quantities of these problematic isotopes, easing the burden on future generations and reducing the need for long-term geological storage solutions.

This intrinsic waste minimization directly addresses one of the most persistent criticisms leveled against nuclear energy. Thorium reactors also offer the potential to ‘breed’ fissile material from fertile isotopes, primarily uranium-233 from thorium-232, thereby potentially reducing the demand for uranium mining and enrichment. This breeding capability enhances resource utilization and contributes to a more sustainable nuclear fuel cycle. Advanced reactor designs, such as accelerator-driven systems (ADS), can be configured to efficiently convert thorium into fissile isotopes, minimizing the need for external fissile material sources and maximizing the energy extracted from each unit of thorium.

This closed-loop approach minimizes reliance on resource-intensive mining operations and lessens the environmental footprint associated with traditional nuclear fuel production. Furthermore, the enhanced safety features inherent in many advanced thorium reactor designs minimize the risk of accidents and environmental contamination. Molten salt reactors, for instance, operate at low pressure and utilize a freeze plug mechanism that automatically shuts down the reactor in the event of an emergency, preventing a runaway reaction and the release of radioactive materials.

This inherent safety characteristic, coupled with the reduced proliferation risk due to the isotopic composition of the spent fuel, positions thorium reactors as a more environmentally responsible and publicly acceptable form of nuclear energy. The focus on safety and waste reduction underscores the commitment to a greener nuclear future, aligning with global efforts to transition towards sustainable energy sources and mitigate climate change. Beyond waste reduction and enhanced safety, the thorium fuel cycle can also contribute to a reduction in carbon emissions associated with the nuclear fuel supply chain. By decreasing the need for uranium enrichment, a highly energy-intensive process, and potentially utilizing thorium resources located in areas with lower environmental sensitivity compared to some uranium mines, the overall carbon footprint of nuclear energy can be further minimized. This holistic approach, encompassing resource efficiency, waste management, and safety enhancements, solidifies the role of thorium reactors in a comprehensive clean energy strategy.

Conclusion: A Sustainable Energy Future with Thorium

Advanced thorium reactor designs offer a compelling vision for the future of nuclear energy, one where energy independence and environmental responsibility converge. With their inherent safety features, such as the passive shutdown mechanisms in molten salt reactors (MSRs), reduced production of long-lived nuclear waste compared to conventional uranium reactors, and an abundant thorium fuel supply distributed across the globe, these advanced reactor designs present a genuine opportunity to transform the energy landscape. They promise a cleaner, safer, and more sustainable energy source for generations to come, potentially mitigating concerns surrounding nuclear proliferation and bolstering global energy security.

The transition to a thorium-based nuclear fuel cycle could drastically reduce the volume and radiotoxicity of waste requiring long-term storage, a critical advantage for public acceptance and environmental protection. While significant technological and economic challenges remain, ongoing research and development efforts are steadily paving the way for a thorium-powered future. Countries like India, possessing substantial thorium reserves, are pioneering the development of advanced heavy water reactors (AHWRs) designed to utilize thorium fuel. China is aggressively pursuing molten salt reactor technology, investing billions in research and development with the goal of achieving commercial deployment in the coming decades.

These global initiatives, coupled with advancements in computational modeling and materials science, are crucial for overcoming the existing hurdles. Overcoming these hurdles will require significant investment in infrastructure, regulatory frameworks, and workforce development to fully realize the potential of thorium reactors. Furthermore, the development of accelerator-driven systems (ADS) offers another pathway for thorium utilization, enhancing control and safety by relying on an external neutron source to sustain the nuclear reaction. This approach allows for subcritical operation, further reducing the risk of runaway reactions.

However, the high capital costs and energy consumption associated with particle accelerators present significant economic barriers that must be addressed. The integration of advanced materials, such as high-performance alloys and ceramics, is also essential to withstand the corrosive environment and intense radiation fields within thorium reactors. Ultimately, the successful deployment of advanced thorium reactors will depend on a concerted effort from governments, industry, and research institutions to foster innovation, address technological challenges, and build public confidence in this promising clean energy technology.