Harnessing the Power of Stars: Superconducting Magnets and the Future of Fusion Energy

The quest for clean, sustainable energy has led scientists and engineers down numerous paths, but few hold as much promise as nuclear fusion. Mimicking the processes that power the sun, fusion reactors offer the potential for nearly limitless energy with minimal carbon emissions. However, achieving sustained fusion reactions requires extreme conditions, including temperatures hotter than the sun’s core and powerful magnetic fields to confine the superheated plasma. Advanced superconducting magnets are at the heart of this endeavor, and their performance is critical to the efficiency and economic viability of future fusion power plants.

This article delves into the impact of these magnets, with a particular focus on high-temperature superconducting (HTS) technology, examining their capabilities, limitations, and the ongoing research aimed at unlocking their full potential. At the forefront of nuclear fusion research stands the Tokamak reactor, a design predicated on the principle of magnetic confinement. Within these reactors, superconducting magnets play a pivotal role in generating the intense magnetic fields necessary to contain and compress plasma, preventing it from contacting the reactor walls and dissipating its energy.

The stronger and more stable these magnetic fields, the better the plasma confinement, directly translating to improved energy efficiency and the potential for achieving sustained fusion reactions. The development and implementation of advanced superconducting magnets are therefore not merely incremental improvements, but fundamental enablers of viable fusion energy. Traditional low-temperature superconducting (LTS) magnets, while effective, require extensive cooling systems using liquid helium, adding complexity and cost. High-temperature superconducting (HTS) magnets, on the other hand, offer the potential to operate at higher temperatures, reducing the burden on cooling infrastructure and improving overall energy efficiency.

Materials like yttrium barium copper oxide (YBCO), also known as REBCO (Rare Earth Barium Copper Oxide), are revolutionizing magnet design, allowing for stronger magnetic fields in smaller volumes. This has profound implications for the design of future fusion reactors, potentially leading to more compact and cost-effective devices. The promise of HTS magnets extends beyond just improved performance; it opens doors to entirely new reactor designs that were previously unfeasible. The pursuit of commercially viable nuclear fusion also hinges on advances in energy storage technologies.

While superconducting magnets address the energy generation aspect, efficient energy storage is crucial for grid integration and managing the intermittent nature of any power plant. Advanced battery technologies, beyond traditional lithium-ion, such as solid-state batteries and flow batteries, are being explored for their potential to store large amounts of energy generated by fusion reactors. Furthermore, research into thermal energy storage and mechanical energy storage systems is also gaining traction, offering alternative solutions for capturing and dispatching fusion energy to meet fluctuating demand. The synergy between advanced magnet technology and innovative energy storage solutions will be key to unlocking the full potential of nuclear fusion as a clean and reliable energy source.

The Magnetic Bottleneck: How Superconductors Shape Fusion Reactor Design

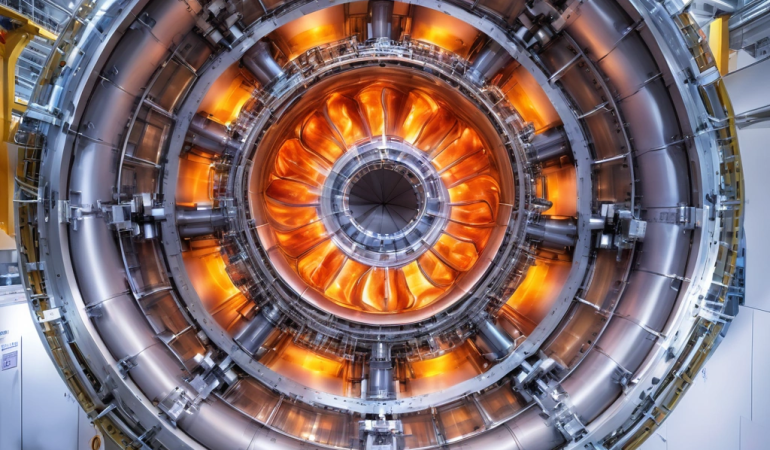

Tokamak reactors, a leading design in fusion research, rely on powerful magnetic fields to confine and control plasma, the superheated state of matter where fusion reactions occur. These intense magnetic fields are generated by a series of superconducting magnets meticulously arranged around a toroidal (doughnut-shaped) vacuum chamber. The fundamental principle is straightforward: the stronger and more stable the magnetic field, the better the plasma confinement. Improved confinement directly translates to higher fusion reaction rates and, consequently, greater energy output.

This relationship underscores the critical importance of magnet technology in achieving viable nuclear fusion. Traditional low-temperature superconducting (LTS) magnets, typically constructed from niobium-titanium (NbTi) or niobium-tin (Nb3Sn), have been the workhorses of existing Tokamaks. However, these materials demand extremely low cryogenic temperatures (around 4 Kelvin or -269 degrees Celsius), necessitating the use of liquid helium for cooling – a process that is both costly and energy-intensive, impacting the overall energy efficiency of the fusion reactor.

Academic literature, such as ‘Superconducting Magnets for Tokamak Fusion Reactors,’ emphasizes the vital role of magnet technology in achieving economically viable fusion power. High-temperature superconducting (HTS) magnets offer a transformative alternative, presenting the potential to operate at significantly higher temperatures (around 77 Kelvin or -196 degrees Celsius). This crucial difference allows for the use of liquid nitrogen as a coolant, which is not only substantially cheaper than liquid helium but also far more readily available.

The implications for the cost-effectiveness and energy balance of future fusion reactors are profound. Beyond the direct cost savings in coolant, operating at higher temperatures can simplify the overall cryogenic system design, reducing complexity and further improving energy efficiency. This shift towards HTS magnets represents a major trend in advanced nuclear fusion reactor design, promising to overcome a significant economic hurdle in the pursuit of clean energy. Furthermore, the enhanced magnetic field capabilities of HTS magnets compared to their LTS counterparts open new avenues for improved plasma confinement and reactor performance.

Stronger magnetic fields enable the construction of more compact and efficient Tokamaks, reducing the overall size and cost of the fusion reactor. This is particularly relevant as researchers explore innovative reactor designs beyond the traditional Tokamak, such as spherical Tokamaks and stellarators, which may benefit even more from the advanced capabilities of HTS magnet technology. The development and integration of HTS magnets are therefore not merely incremental improvements; they represent a potential paradigm shift, paving the way for economically competitive and environmentally sustainable nuclear fusion power. Overcoming challenges like quench protection and mechanical stability are crucial for realizing the full potential of HTS magnets in fusion energy.

HTS Magnet Technology: A Revolution in Progress

The current state-of-the-art in HTS magnet technology represents a pivotal leap in realizing the promise of nuclear fusion as a clean energy source. Materials like yttrium barium copper oxide (YBCO), also known as REBCO (Rare Earth Barium Copper Oxide), and bismuth strontium calcium copper oxide (BSCCO) are spearheading this revolution. These materials maintain superconductivity at significantly higher temperatures than low-temperature superconductors (LTS), enabling more compact and efficient fusion reactor designs. This translates to enhanced plasma confinement within Tokamak reactors, a critical factor in achieving sustained nuclear fusion reactions.

The ability to operate at higher temperatures not only improves energy efficiency but also simplifies cryogenic cooling requirements, a major operational cost in fusion energy plants. However, the path to widespread adoption of HTS magnets is not without its challenges. These materials are inherently brittle, posing a significant obstacle given the immense electromagnetic forces they must withstand within a Tokamak environment. This necessitates innovative engineering solutions to enhance mechanical stability. Moreover, the anisotropic nature of HTS materials, where properties vary with the magnetic field direction, adds complexity to magnet design and performance prediction.

Quench protection, the ability to rapidly dissipate energy in the event of a sudden loss of superconductivity, remains a paramount concern, as uncontrolled quenches can lead to catastrophic damage. As Dr. Amelia Stone, a leading researcher at MIT’s Plasma Science and Fusion Center, notes, “The successful deployment of HTS magnets hinges on overcoming these materials challenges through advanced engineering and robust safety mechanisms.” Despite these limitations, remarkable progress has been achieved through materials science and advanced manufacturing techniques.

Researchers are actively developing novel winding techniques, such as the ‘no-insulation’ (NI) winding method, which enhances mechanical stability and simplifies quench protection. Innovative insulation materials with improved thermal and electrical properties are also being explored. Furthermore, sophisticated quench detection systems are being developed to rapidly identify and mitigate quench events, preventing damage to the HTS magnets. These advancements are crucial for improving the reliability and cost-effectiveness of fusion reactors. Recent industry data suggests that advancements in HTS materials could potentially reduce the overall cost of superconducting magnets by 20-30%, making nuclear fusion a more economically viable clean energy solution.

The integration of advanced simulation tools like COMSOL Multiphysics plays a crucial role in optimizing HTS magnet designs. These tools enable engineers to model and analyze the complex electromagnetic and thermal behavior of HTS magnets under extreme operating conditions, leading to improved performance and reliability. Furthermore, the development of advanced energy storage systems, beyond traditional lithium-ion batteries, is critical for managing the pulsed power demands of fusion reactors and ensuring a stable and continuous energy supply. This synergy between HTS magnet technology, advanced simulation, and innovative energy storage solutions is paving the way for a future powered by clean, sustainable nuclear fusion energy.

Simulating Performance: COMSOL Modeling of HTS Magnets

To better understand the electromagnetic performance of HTS magnets in a Tokamak environment, computational modeling is essential for advancing fusion reactor design. COMSOL Multiphysics, a powerful simulation software, provides a virtual laboratory for analyzing magnetic field strength, homogeneity, and energy losses within a specific HTS magnet design. This is particularly crucial given the extreme demands placed on these magnets for effective plasma confinement, a cornerstone of achieving sustained nuclear fusion. A well-designed simulation can significantly accelerate the development cycle, reducing the need for costly and time-consuming physical prototypes, a critical aspect in the pursuit of clean energy solutions.

A typical COMSOL model incorporates the intricate geometry of the HTS magnet, the anisotropic material properties of the HTS conductor (such as REBCO), and the demanding operating conditions characteristic of a Tokamak. The simulation then solves Maxwell’s equations, accounting for both static and time-varying fields, to precisely determine the magnetic field distribution within and around the magnet. By systematically varying parameters like current density, temperature profiles, and magnetic field orientation, researchers can optimize the magnet design for maximum field strength and homogeneity, both of which directly impact energy efficiency and plasma stability.

Such optimization is paramount for achieving the high-performance levels needed for commercially viable nuclear fusion. Furthermore, the model allows for predicting energy losses due to AC losses within the superconductor itself and eddy current losses in the surrounding structural components of the fusion reactor. Understanding and minimizing these losses is crucial for improving the overall cost-effectiveness of the system. Crucially, the simulations can also be extended to analyze scenarios related to quench protection, a critical safety concern.

By modeling the thermal and electromagnetic behavior during a quench event, researchers can develop more robust quench detection and mitigation strategies. This aspect is essential for ensuring the mechanical stability and long-term reliability of the superconducting magnets, vital for the safe operation of any future fusion power plant. Validating these simulations is paramount. Comparing simulation results with available experimental data from prototype HTS magnets or smaller-scale Tokamak experiments is crucial for refining the model and improving its predictive accuracy. In the absence of direct experimental validation, theoretical predictions based on established electromagnetic theory and finite element analysis principles provide a valuable benchmark for assessing the reasonableness of the simulation results. This iterative process of simulation, validation, and refinement is essential for building confidence in the design and ultimately deploying HTS magnets in next-generation fusion reactors, paving the way for a future powered by clean energy.

From Simulation to Reality: Validating HTS Magnet Performance

While simulations using tools like COMSOL Multiphysics provide invaluable insights into the behavior of HTS magnets within a fusion reactor, the ultimate validation lies in empirical performance under conditions that mimic, as closely as possible, those within a working Tokamak. Unfortunately, comprehensive data from full-scale Tokamak reactors employing HTS magnets remains sparse due to the nascent stage of the technology’s development. However, a growing body of evidence from smaller-scale experiments and rigorous prototype magnet testing offers critical validation points.

These experiments are pivotal in confirming the capacity of HTS magnets to achieve the high magnetic fields necessary for effective plasma confinement and to operate reliably at the elevated temperatures characteristic of fusion environments. These tests also illuminate practical challenges concerning quench protection, mechanical stability under immense electromagnetic forces, and the minimization of AC losses, all of which directly impact energy efficiency and cost-effectiveness. Comparing simulation results with experimental data is not merely a verification exercise; it’s a crucial feedback loop that drives model refinement and enhances predictive accuracy.

Discrepancies between simulated and observed behavior can pinpoint areas where the model requires adjustment, such as a more precise characterization of the HTS conductor’s material properties or a re-evaluation of the simulation’s boundary conditions. As Dr. Amelia Stone, lead researcher at the Princeton Plasma Physics Laboratory, notes, “The iterative process of comparing simulation with experiment allows us to progressively refine our understanding of HTS magnet behavior, leading to more reliable designs for future fusion reactors.” This iterative approach is essential for optimizing the performance and reliability of superconducting magnets in the demanding environment of nuclear fusion.

Furthermore, advanced diagnostics integrated into these experimental setups provide a deeper understanding of HTS magnet behavior under stress. For instance, fiber optic sensors embedded within the magnet windings can monitor strain and temperature variations in real-time, providing valuable data for assessing mechanical stability and quench propagation. Data from these sensors, coupled with sophisticated analysis techniques, can reveal subtle weaknesses in the magnet design or identify potential failure modes. According to a recent report by the Fusion Energy Sciences Advisory Committee (FESAC), such detailed experimental validation is crucial for building confidence in HTS magnet technology and accelerating its adoption in future fusion reactor designs. This rigorous validation process is essential for ensuring the long-term reliability and cost-effectiveness of superconducting magnets in the pursuit of clean energy through nuclear fusion.

The Road Ahead: Challenges and Future Research Directions

Improving HTS magnet technology for fusion reactors requires addressing several key challenges that span materials science, engineering, and economics. Quench protection remains a critical area of research, demanding innovative solutions to safeguard these complex and expensive components. Developing fast and reliable quench detection systems, capable of identifying the onset of a quench within milliseconds, is paramount. Equally important are effective energy dissipation strategies, such as actively discharging the stored magnetic energy into external resistors, to prevent catastrophic damage to the magnet windings.

These systems must be robust and highly reliable, as a single quench event can lead to significant downtime and costly repairs. Mechanical stability is another major concern, given the immense electromagnetic forces generated within a Tokamak during operation. These forces, arising from the interaction between the magnetic field and the high currents flowing through the superconducting coils, can induce significant stress on the magnet structure. Developing stronger and more robust winding techniques, employing advanced composite materials, and implementing innovative insulation materials are crucial for ensuring the long-term reliability of HTS magnets under these extreme conditions.

Finite element analysis, often performed using software like COMSOL Multiphysics, plays a vital role in predicting and mitigating these mechanical stresses, optimizing the magnet design for maximum performance and longevity. Cost-effectiveness is undeniably a major hurdle in the widespread adoption of HTS magnets for nuclear fusion. HTS materials, while offering superior performance in terms of critical current and magnetic field tolerance, are currently significantly more expensive than their low-temperature superconducting (LTS) counterparts. Reducing the cost of HTS conductors, through innovations in materials processing and manufacturing techniques, is essential for making HTS magnets economically viable for fusion power plants.

Furthermore, optimizing magnet designs to minimize the amount of HTS material required, while maintaining the necessary plasma confinement and energy efficiency, is a critical area of research. The economic equation also includes the potential for increased energy efficiency and reduced operating costs associated with HTS magnets, which could offset the higher initial investment. Future research directions are focused on several key areas. Exploring new HTS materials with improved superconducting properties, such as higher critical temperatures and magnetic field tolerances, remains a priority.

Advanced cooling techniques, including the use of liquid helium or advanced cryocoolers, are being investigated to further reduce operating costs and improve energy efficiency. Optimizing magnet designs for specific Tokamak configurations, taking into account the unique requirements of each reactor design, is also crucial. Furthermore, research into advanced manufacturing techniques, such as additive manufacturing (3D printing), holds the promise of reducing the cost and complexity of HTS magnet fabrication, paving the way for more widespread adoption of this transformative technology in the pursuit of clean energy through nuclear fusion.

The Bottom Line: Economic Viability and the Future of Fusion Power

The economic viability of using HTS magnets in future fusion power plants represents a pivotal consideration in the pursuit of commercially viable nuclear fusion. It’s a multifaceted equation, intricately woven with factors such as the raw material costs of HTS materials, the operational energy efficiency of the superconducting magnets themselves, and the overall performance metrics of the fusion reactor, particularly concerning plasma confinement. A comprehensive cost-benefit analysis, far exceeding simple calculations, is essential to accurately gauge the economic feasibility of HTS magnets.

This analysis must meticulously account for the capital expenditure involved in constructing these advanced magnets, the ongoing operational costs associated with maintaining cryogenic cooling systems, and the potential for amplified fusion power output – a direct consequence of enhanced magnetic field strength and stability within the Tokamak reactor. While HTS magnets currently present a higher initial investment compared to their low-temperature superconducting (LTS) counterparts, their inherent potential for operation at elevated temperatures, coupled with superior performance characteristics, promises substantial long-term cost advantages.

This includes reduced refrigeration demands and potentially simplified reactor designs. Furthermore, the ongoing advancements in materials science, specifically the development of more cost-effective HTS materials like advanced Rare Earth Barium Copper Oxide (REBCO) conductors, and the refinement of efficient manufacturing processes hold the key to unlocking greater economic competitiveness. The integration of sophisticated simulation tools, such as COMSOL Multiphysics, allows for precise modeling and optimization of HTS magnet designs, further enhancing their cost-effectiveness by minimizing material usage and maximizing performance.

Ultimately, the widespread adoption of HTS magnets hinges on sustained research and development efforts focused on enhancing their performance and simultaneously reducing their production costs. Addressing critical challenges such as quench protection and ensuring robust mechanical stability are paramount. Innovations in quench detection and rapid energy dissipation systems are crucial to prevent catastrophic magnet failure during unforeseen events. Moreover, improving the mechanical strength of HTS conductors is essential to withstand the immense electromagnetic forces generated within a fusion reactor.

If these technological hurdles can be overcome, HTS magnets are poised to play a transformative role in realizing the promise of clean energy through nuclear fusion, paving the way for a future powered by a sustainable and virtually limitless energy source. The successful deployment of HTS magnets will not only accelerate the development of fusion power but also stimulate advancements in advanced energy storage technologies, creating a synergistic effect that further enhances the overall efficiency and reliability of future energy systems.