Harnessing the Unseen: The Promise of Thermoelectric Generators

In an era defined by escalating energy demands and pressing environmental concerns, the imperative to optimize energy utilization has never been more critical. A vast, often overlooked resource lies dormant within the industrial sector: waste heat. Thermoelectric generators (TEGs) offer a promising avenue for capturing this wasted energy and converting it into usable electricity. These solid-state devices, based on the Seebeck effect, directly transform temperature differences into electrical energy, presenting a clean and sustainable alternative to traditional power generation methods.

From the sprawling factories of the industrial heartland to the intricate machinery of luxury properties, TEGs are poised to revolutionize how we perceive and manage energy. Imagine household managers in luxury properties, leveraging TEGs to recapture heat from HVAC systems or kitchen appliances, turning what was once a loss into a source of supplemental power. TEGs represent a significant advancement in advanced thermal energy harvesting, offering a pathway to enhance industrial energy efficiency and promote sustainable energy practices.

Unlike traditional energy generation methods that often rely on fossil fuels and contribute to greenhouse gas emissions, TEGs harness waste heat recovery, converting it into a clean energy source. The potential impact on energy conservation is substantial; studies suggest that widespread adoption of waste heat recovery systems utilizing TEGs could reduce global energy consumption by several percentage points, a considerable step towards meeting international climate goals. This makes exploring novel thermoelectric materials and innovative TEG system designs crucial for maximizing thermoelectric generator efficiency.

However, realizing the full potential of TEG applications requires overcoming existing challenges. Improving thermoelectric materials to enhance energy harvesting capabilities is paramount. Research into nanomaterials and segmented TEGs is showing promise in boosting thermoelectric generator efficiency across a broader temperature range. Furthermore, effective thermal management strategies are essential for maintaining the necessary temperature gradient for optimal TEG performance. Overcoming these hurdles will pave the way for more widespread integration of TEGs in diverse sectors, driving industrial innovation and fostering a more sustainable energy future. The development and implementation of robust waste heat recovery systems are not merely technological advancements; they represent a fundamental shift towards a circular economy, where energy is valued and reused rather than discarded.

Advanced Materials: The Key to Enhanced Efficiency

The heart of a TEG lies in its thermoelectric material, which dictates its efficiency and performance. Traditional TEG materials, such as bismuth telluride (Bi2Te3), have limitations in terms of operating temperature and conversion efficiency, typically exhibiting a dimensionless figure of merit (ZT) around 1. However, recent advancements in materials science have yielded a new generation of high-performance thermoelectric materials. Nanomaterials, for example, offer enhanced thermoelectric generator efficiency due to quantum confinement effects and increased phonon scattering, which reduces thermal conductivity and improves the figure of merit (ZT). ‘The development of novel thermoelectric materials is crucial for unlocking the full potential of TEG technology,’ says Dr.

Evelyn Hayes, a leading materials scientist at MIT. Segmented TEGs, which combine different thermoelectric materials with varying optimal temperature ranges, are another promising approach. By tailoring the material composition to the specific temperature gradient, segmented TEGs can achieve higher overall conversion efficiencies, crucial for maximizing energy harvesting from variable waste heat sources. These advancements are directly impacting the feasibility of TEG applications in diverse industrial settings. The pursuit of enhanced thermoelectric materials is driving innovation in several key areas.

Researchers are exploring skutterudites, half-Heusler alloys, and metal-organic frameworks (MOFs) as potential candidates for next-generation TEGs. Skutterudites, for instance, offer high power factors but often suffer from high thermal conductivity. Strategies to introduce phonon scattering centers, such as through the incorporation of nanoparticles or rattling atoms within the crystal structure, are being employed to mitigate this limitation. Half-Heusler alloys, known for their thermal stability and mechanical robustness, are also gaining traction, particularly for high-temperature waste heat recovery systems.

These materials are crucial for advanced thermal energy harvesting and represent a significant leap forward in sustainable energy technology. Furthermore, advancements in TEG system design are complementing the progress in materials science. Innovative thermal management strategies, including the use of microchannel heat exchangers and phase change materials, are being implemented to optimize heat transfer and maintain a stable temperature gradient across the thermoelectric modules. The integration of TEGs into existing industrial processes requires careful consideration of factors such as heat source characteristics, operating temperature range, and mechanical constraints.

For example, in cement manufacturing, where significant amounts of waste heat are released, TEGs can be integrated into the exhaust stacks to generate electricity, contributing to industrial energy efficiency and reducing carbon emissions. Such TEG applications exemplify the potential for waste heat recovery to transform industrial operations. The convergence of advanced materials, optimized TEG system design, and innovative thermal management strategies is paving the way for wider adoption of thermoelectric generators. As the cost of high-performance thermoelectric materials decreases and manufacturing processes become more scalable, TEG technology is poised to play an increasingly significant role in energy conservation and renewable energy initiatives. The development of efficient and cost-effective TEGs is not just an academic pursuit; it is a critical step towards a more sustainable and energy-secure future, unlocking the vast potential of waste heat recovery.

System Design: Optimizing Heat Transfer and Integration

Beyond the thermoelectric material itself, the TEG system design plays a crucial role in maximizing energy harvesting efficiency. Effective thermal management is paramount, as thermoelectric generators require a significant temperature difference to operate effectively. Heat sinks, heat pipes, and other thermal management strategies are used to dissipate heat from the cold side of the TEG and maintain a high-temperature gradient. The geometry and configuration of the TEG module also influence its performance. Optimizing the number of thermoelectric couples, their dimensions, and their arrangement can significantly enhance power output. ‘A well-designed TEG system considers every aspect of the heat transfer process, from the heat source to the heat sink,’ explains Professor David Chen, an expert in thermal engineering at Stanford University.

The integration of TEGs with existing waste heat recovery systems also requires careful consideration. For example, in industrial settings, TEGs can be integrated with exhaust stacks, furnaces, and other heat-generating equipment to capture waste heat directly at the source, contributing to industrial energy efficiency. Achieving optimal thermoelectric generator efficiency involves a holistic approach that extends beyond merely selecting high-performing thermoelectric materials. The design must account for the specific characteristics of the heat source and the intended TEG applications.

This includes analyzing the temperature profile, flow rate, and chemical composition of the waste heat stream. For instance, integrating TEGs into a cement manufacturing plant’s exhaust system requires a design robust enough to withstand high temperatures and corrosive gases. Advanced thermal energy harvesting solutions also consider the use of segmented TEGs, which employ different thermoelectric materials optimized for different temperature ranges within the same device. This allows for a broader operating temperature range and improved overall efficiency.

Nanomaterials are also playing an increasing role in enhancing thermal conductivity and reducing parasitic heat losses within the TEG system, further boosting energy harvesting capabilities. Sophisticated thermal management strategies are indispensable for maximizing the performance of TEG-based waste heat recovery systems. These strategies often involve the use of advanced heat exchangers, microchannel heat sinks, and even phase-change materials to effectively transfer heat to the hot side of the TEG and dissipate heat from the cold side.

Effective thermal management not only enhances energy harvesting but also prolongs the lifespan of the TEG module by preventing overheating and thermal stress. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are commonly employed to optimize the TEG system design and ensure efficient heat transfer. These simulations enable engineers to predict temperature distributions, heat fluxes, and pressure drops within the system, allowing for informed design decisions that maximize energy conservation and promote sustainable energy practices. By optimizing TEG system design, we unlock the full potential of thermoelectric technology for a cleaner and more efficient industrial landscape, contributing significantly to renewable energy goals and clean energy initiatives.

Practical Applications: From Automotive to Industrial Settings

TEG technology is rapidly transitioning from laboratory curiosity to industrial mainstay, finding diverse applications from automotive engineering to heavy manufacturing. In the automotive sector, the relentless pursuit of improved fuel efficiency and reduced emissions has led major manufacturers like BMW to aggressively explore TEG integration for exhaust heat recovery. These efforts aim to convert wasted thermal energy into usable electricity, reducing the load on the alternator and boosting overall fuel economy. Early prototypes have demonstrated the potential for a 5% to 10% improvement in fuel efficiency, a significant leap in an industry striving for incremental gains.

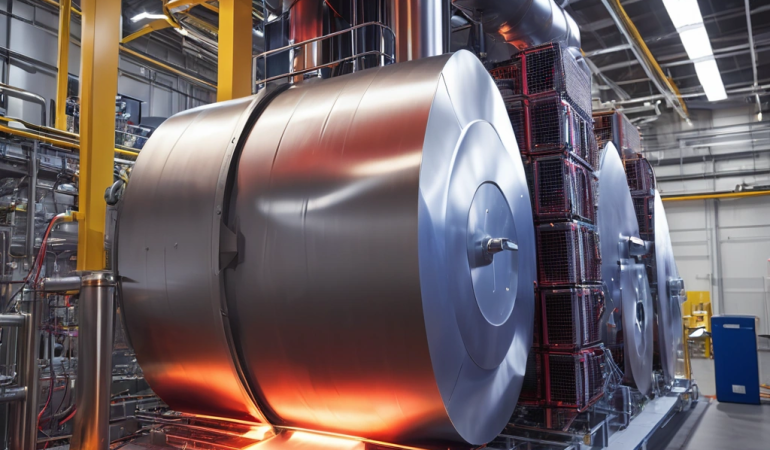

This translates directly into lower greenhouse gas emissions and reduced reliance on fossil fuels, aligning with global sustainability goals. The development of advanced thermoelectric materials, particularly nanomaterials, is further accelerating progress in this area, promising even higher thermoelectric generator efficiency and more compact TEG system design. Beyond automotive, the industrial sector represents a vast, largely untapped reservoir of waste heat. Power plants, steel mills, cement factories, and chemical processing facilities all generate substantial amounts of thermal energy as a byproduct of their operations.

Integrating waste heat recovery systems utilizing TEGs offers a compelling pathway to improve industrial energy efficiency and reduce carbon footprints. A German steel mill’s implementation of a TEG system to capture waste heat from its furnaces resulted in a documented 15% reduction in energy consumption and a corresponding decrease in carbon emissions, showcasing the tangible economic and environmental benefits. According to a recent report by the International Energy Agency (IEA), waste heat recovery technologies, including TEGs, could potentially reduce global industrial energy consumption by 10% to 20%.

Furthermore, innovative TEG applications are emerging in niche sectors. Remote power generation for sensors and monitoring equipment in harsh environments, such as oil and gas pipelines or arctic research stations, is becoming increasingly feasible. These applications leverage the inherent reliability and low maintenance requirements of TEGs, making them ideal for situations where access to conventional power sources is limited or impractical. Segmented TEGs, which utilize different thermoelectric materials optimized for different temperature ranges, are further expanding the applicability of this technology.

As research continues to push the boundaries of thermoelectric materials and TEG system design, we can expect to see even more widespread adoption of advanced thermal energy harvesting technologies across a multitude of industries, contributing to a more sustainable and energy-efficient future. Effective thermal management strategies are crucial for optimizing TEG performance in these diverse environments, ensuring maximum energy harvesting and long-term operational stability. The ongoing advancements in energy harvesting are making TEGs a key component in the transition to clean energy.

Challenges and Opportunities: Paving the Way for Widespread Adoption

Despite the numerous advantages of TEG technology, several challenges remain that hinder its widespread adoption. Cost is a major barrier, as high-performance thermoelectric materials can be expensive to produce. Scalability is another concern, as manufacturing TEG modules on a large scale requires significant investment in infrastructure and equipment. Integration with existing energy systems can also be complex, requiring careful engineering and design. However, these challenges also present opportunities for innovation and improvement. Research efforts are focused on developing low-cost thermoelectric materials, such as earth-abundant compounds and organic materials.

Advances in manufacturing techniques, such as 3D printing and thin-film deposition, are paving the way for more scalable and cost-effective TEG production. ‘Overcoming these challenges will require a concerted effort from researchers, engineers, and policymakers,’ says Sarah Johnson, an energy analyst at BloombergNEF. The pursuit of enhanced thermoelectric generator efficiency is driving innovation across several fronts within advanced thermal energy harvesting. One promising area lies in the development of segmented TEGs, which utilize multiple thermoelectric materials optimized for different temperature ranges within the same device.

This approach allows for a broader operating temperature window and improved overall energy harvesting performance compared to single-material TEGs. Furthermore, advancements in TEG system design are crucial for maximizing waste heat recovery systems. Sophisticated thermal management strategies, including advanced heat sinks and microchannel heat exchangers, are being employed to optimize heat transfer and maintain the necessary temperature gradient for efficient energy conversion. These innovations are particularly relevant in industrial energy efficiency, where large quantities of waste heat are readily available.

Nanomaterials are revolutionizing the field of thermoelectric materials, offering unprecedented opportunities to enhance thermoelectric properties. By manipulating the structure and composition of materials at the nanoscale, researchers are able to engineer materials with higher Seebeck coefficients, lower thermal conductivity, and improved electrical conductivity – all crucial factors for boosting thermoelectric performance. For example, quantum dots and nanowires can scatter phonons, reducing thermal conductivity without significantly affecting electrical conductivity, thereby increasing the figure of merit (ZT) of the material, a key indicator of thermoelectric efficiency.

The development of these advanced thermoelectric materials is vital for expanding TEG applications and promoting sustainable energy solutions. Addressing the scalability challenge requires a multi-pronged approach encompassing materials synthesis, module fabrication, and system integration. Researchers are exploring high-throughput synthesis techniques to produce large quantities of nanomaterials and other advanced thermoelectric materials at reduced cost. Furthermore, innovative module fabrication methods, such as thin-film deposition and screen printing, are being developed to automate the manufacturing process and improve production yields. Finally, standardized TEG system design and integration protocols are needed to facilitate the seamless incorporation of TEGs into existing industrial processes and energy infrastructure. Overcoming these hurdles will unlock the full potential of TEGs for waste heat recovery and contribute significantly to energy conservation and the broader adoption of renewable energy and clean energy technologies.

Technology Selection: Tailoring TEGs to Specific Applications

Selecting the appropriate TEG technology for a specific application demands a nuanced understanding of interconnected factors. The temperature gradient, the linchpin of thermoelectric generator efficiency, directly dictates the potential power output. However, a singular focus on delta-T is insufficient. A comprehensive evaluation necessitates scrutinizing the heat source characteristics – temperature, flow rate, composition, and stability – as these parameters fundamentally influence the choice of thermoelectric materials and the overall TEG system design. Discrepancies between theoretical models and real-world conditions can significantly impact performance, underscoring the importance of empirical data and pilot studies.

The desired power output, intrinsically linked to the application’s energy demands, dictates the number of TEG modules and their optimal configuration, driving system cost and complexity. For high-temperature environments, such as those encountered in industrial furnaces or concentrated solar power plants, segmented TEGs incorporating advanced thermoelectric materials like skutterudites or half-Heusler alloys are often the most viable option. These materials exhibit superior thermal stability and maintain reasonable thermoelectric generator efficiency at elevated temperatures, crucial for maximizing energy harvesting from intense heat sources.

Conversely, low-temperature waste heat recovery systems, such as those scavenging energy from electronic devices or automotive exhaust, may find bismuth telluride-based TEGs or emerging nanomaterials more suitable, balancing cost-effectiveness with acceptable performance. The selection process must also consider the long-term operational stability of the thermoelectric materials under the specific temperature and chemical environment. Beyond material selection, effective thermal management strategies are crucial for optimizing TEG performance. This includes the integration of heat sinks, heat pipes, or other advanced cooling technologies to maintain a substantial temperature difference across the TEG module.

Furthermore, the electrical load matching between the TEG and the power conditioning circuitry is critical to maximize the power transfer efficiency. A poorly designed interface can negate the benefits of even the most efficient thermoelectric materials. A thorough assessment of the application requirements, encompassing both thermal and electrical considerations, is therefore essential for selecting the most appropriate and cost-effective TEG technology, ensuring a robust and sustainable energy harvesting solution that contributes to industrial energy efficiency and promotes the adoption of clean energy technologies. The future of advanced thermal energy harvesting hinges on this holistic approach to TEG system design.

The Future of Energy: A Sustainable Vision with Thermoelectric Generators

Thermoelectric generators represent a compelling solution for waste heat recovery, offering a pathway towards a more sustainable and energy-efficient future. With ongoing advancements in materials science, system design, and manufacturing techniques, TEG technology is poised to play an increasingly important role in various sectors, from industrial manufacturing to luxury residential properties. By harnessing the potential of waste heat, we can reduce our reliance on fossil fuels, lower carbon emissions, and create a cleaner, more sustainable world.

The journey towards widespread adoption may present challenges, but the rewards are well worth the effort. As Dr. Hayes aptly puts it, ‘Thermoelectric generators are not just a technology; they are a paradigm shift in how we think about energy.’ Looking ahead, the convergence of advanced thermal energy harvesting techniques with sophisticated industrial energy efficiency programs promises significant breakthroughs. The development of novel thermoelectric materials, particularly nanomaterials and segmented TEGs designed for specific temperature ranges, is crucial for boosting thermoelectric generator efficiency.

Furthermore, optimized TEG system design, incorporating advanced thermal management strategies, is paramount to maximizing energy harvesting from diverse waste heat sources. Consider, for instance, the potential of integrating TEGs into existing waste heat recovery systems within power plants or manufacturing facilities to generate supplementary clean energy, reducing overall energy consumption and environmental impact. Addressing the scalability and cost-effectiveness of TEG technology remains a central focus for researchers and engineers. Innovative manufacturing processes and material sourcing strategies are essential to drive down production costs and make TEG applications more economically viable.

Simultaneously, ongoing research into advanced thermal energy harvesting is exploring new avenues for improving the long-term stability and durability of thermoelectric devices. The development of robust TEG modules capable of withstanding harsh industrial environments will be critical for widespread adoption in demanding applications. Success in these areas will unlock the full potential of TEGs as a cornerstone of sustainable energy and energy conservation efforts. Ultimately, the future success of TEG technology hinges on collaborative efforts between researchers, industry stakeholders, and policymakers to overcome existing barriers and foster innovation.

Incentivizing investment in TEG research and development, establishing clear regulatory frameworks for waste heat recovery, and promoting public awareness of the benefits of thermoelectric generators will be crucial for accelerating their deployment. By embracing the potential of TEGs, we can pave the way for a more sustainable and energy-efficient future, where waste heat is no longer a lost resource but a valuable source of renewable energy, contributing to a cleaner and more prosperous world. The integration of TEGs with other renewable energy sources further strengthens the path towards a truly sustainable energy ecosystem.